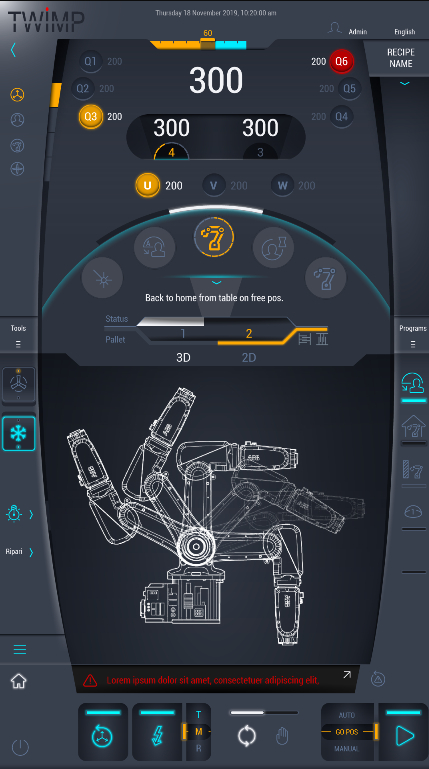

Laser applications.

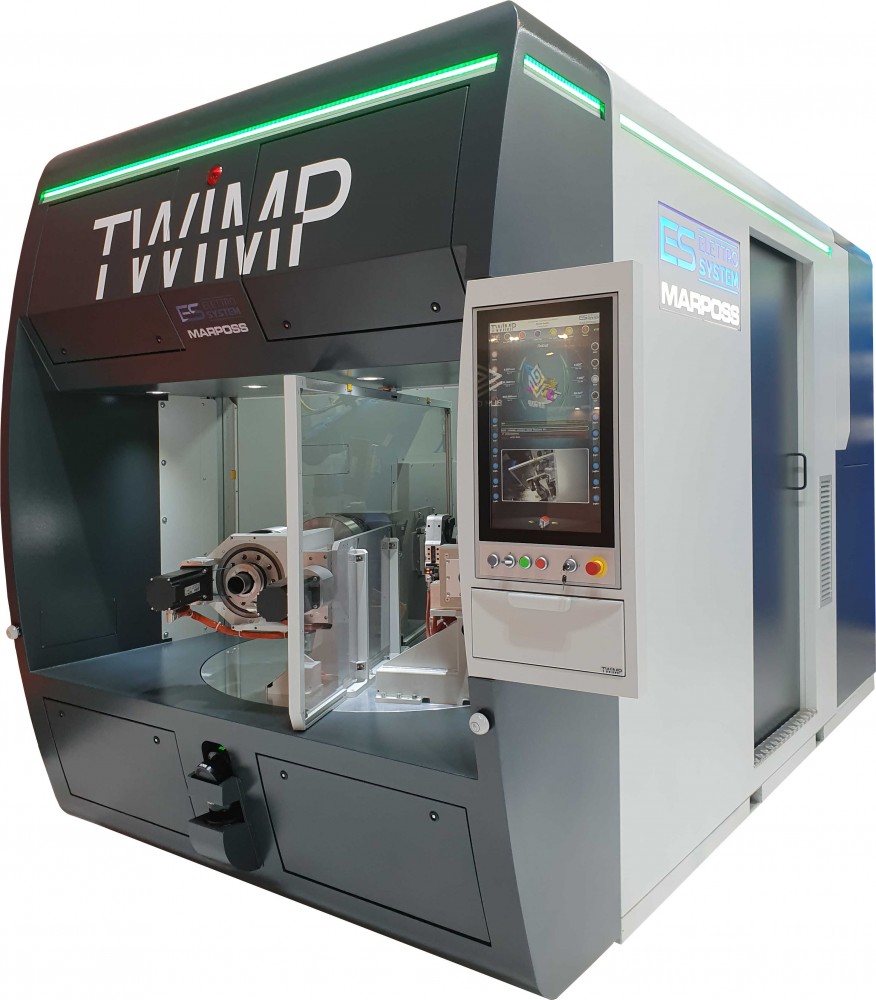

TWIMP, the product is not only the machine itself!

TWIMP is an internal Business Unit of Elettrosystem with dedicated spaces and people voted to the laser world. A context highly specialized to ensure high and specialized competences to guarantee the best customer's satisfaction.

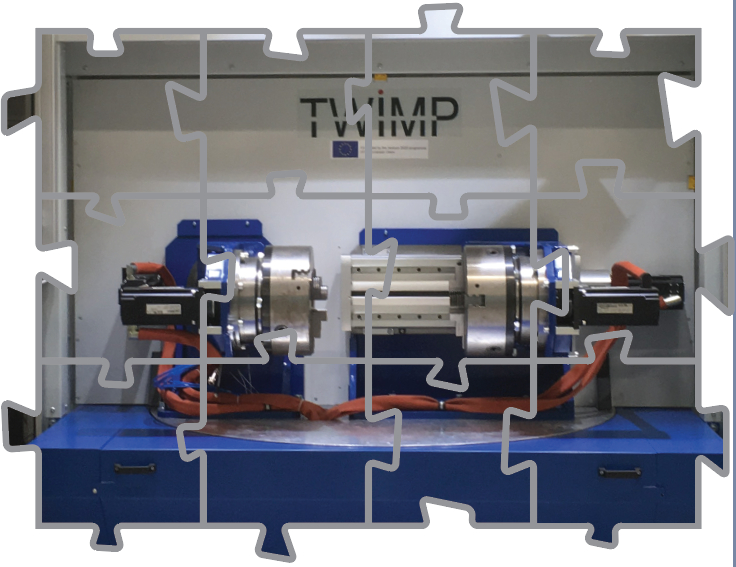

TWIMP, the machine

TWIMP is a machine technologically at the cutting edge for the laser works through a 3D automatic system. Born as output of a H2020 Phase II project, co-funded by the Eurpean Commission, it encloses the whole experience matured with the experimentation of Elettrosystem. The system, very accurate is developed having in mind the efficency the production should have, the reduction of its manufacturing steps and the relative costs; the configuration of the machine is tailored on the range of products the same machine is intended. TWIMP is in fact the solution to combine the quality with the praticity in the working of products/semiworked goods with volumes relatively small and complex geometries.

TWIMP, the people

TWIMP is a company division with young technicians, volcaninc minds, resourceful and very competent. Each aspect of a TWIMP project is under the care of a tight-knit team reach of skills about software, hardware and mechanical design and laser process finalisation. Moreover, the Application responsible is a certified Safty Laser Officer.

TWIMP machine

Appreciable characteristics of TWIMP machine are:

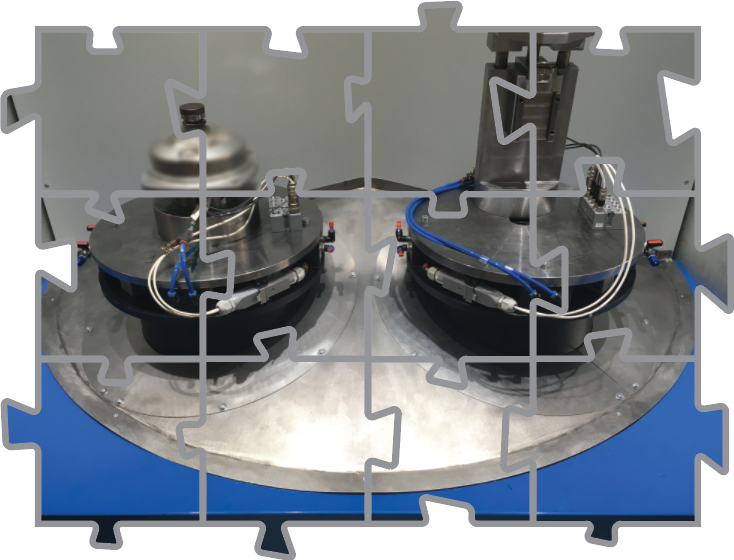

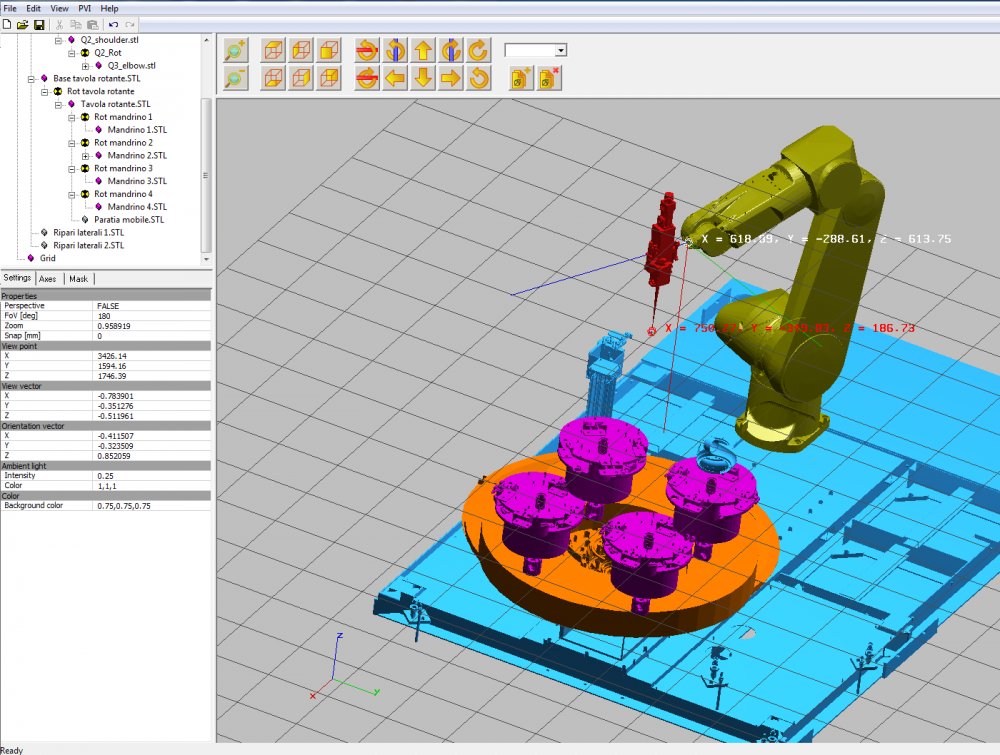

FORM FACTOR TWIMP is available with two basic form factors: a bench and a robotized cell.

CONFIGURABILITY One of the strengths of TWIMP is the possibility to be customizable unit by unit. Not just a mere configuration for the jigs arrangement, but a real design of operator or tending system interaction side.

INDUSTRY 4.0 Not only interoperability with MES/ERP, as it's usually intended the fourth industrial revolution, but much calculation capability, as well, to service the CN-PLC to govern the robotic arm with the highest care of the operator and the machine itself..

TWIMP processes

Elettrosystem is not bounded by any laser device manufacturer or distributor; on the contrary, the best equipment are selected from the market as what most appropriate is available for the specific application at the moment of the feasibility evaluation and machine configuration. Aimed of this spirit, Elettrosystem proposes TWIMP machines provided of the optimal combination of source-fiber-head and chiller respect the specific customer's need.

The integrated equipment are only from primary producers with a robust and reliable network of spares distribution and a responsive technical support word-widely. TWIMP machines are suitable for all processes performable through fiber or diode laser only.

This paradigm allows TWIMP to be declined among all of those processes these technologies make available: cutting, welding, hardening, coating.

CUTTING Cutting itself is a very mature process in the industrial laser works, TWIMP could be an enrichment in case of three-dimensionality.

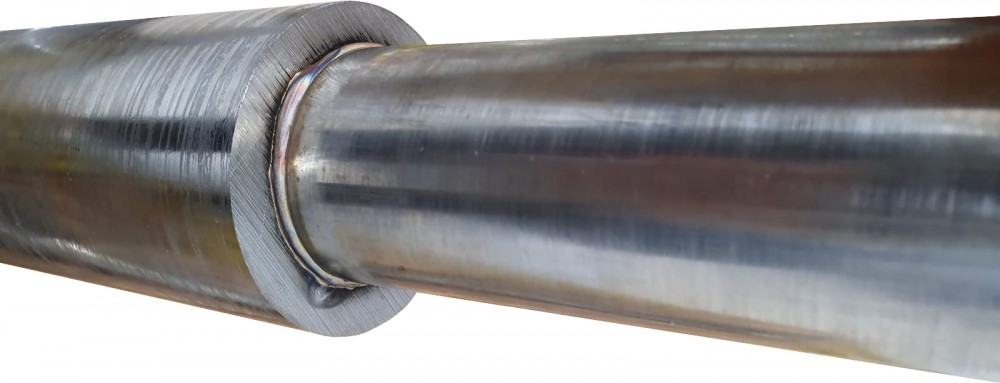

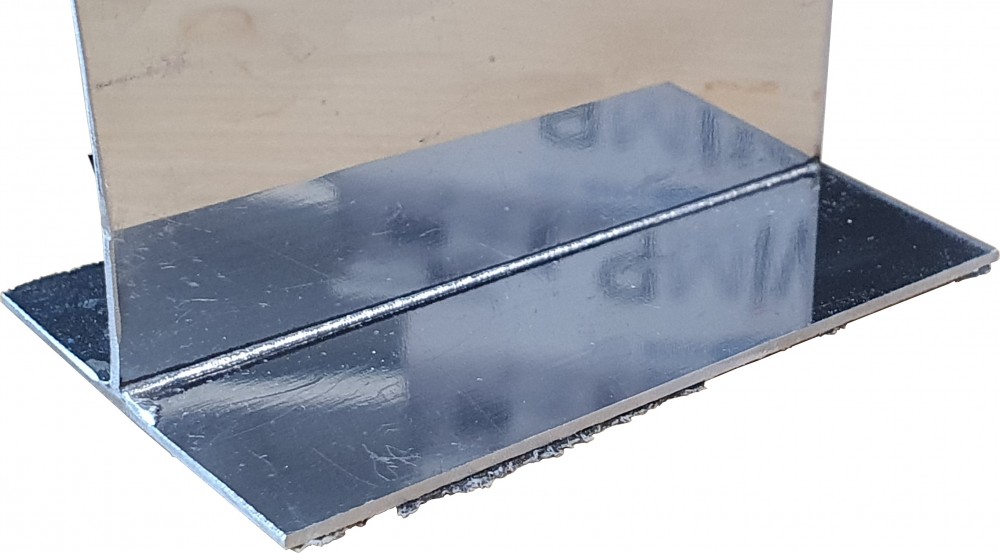

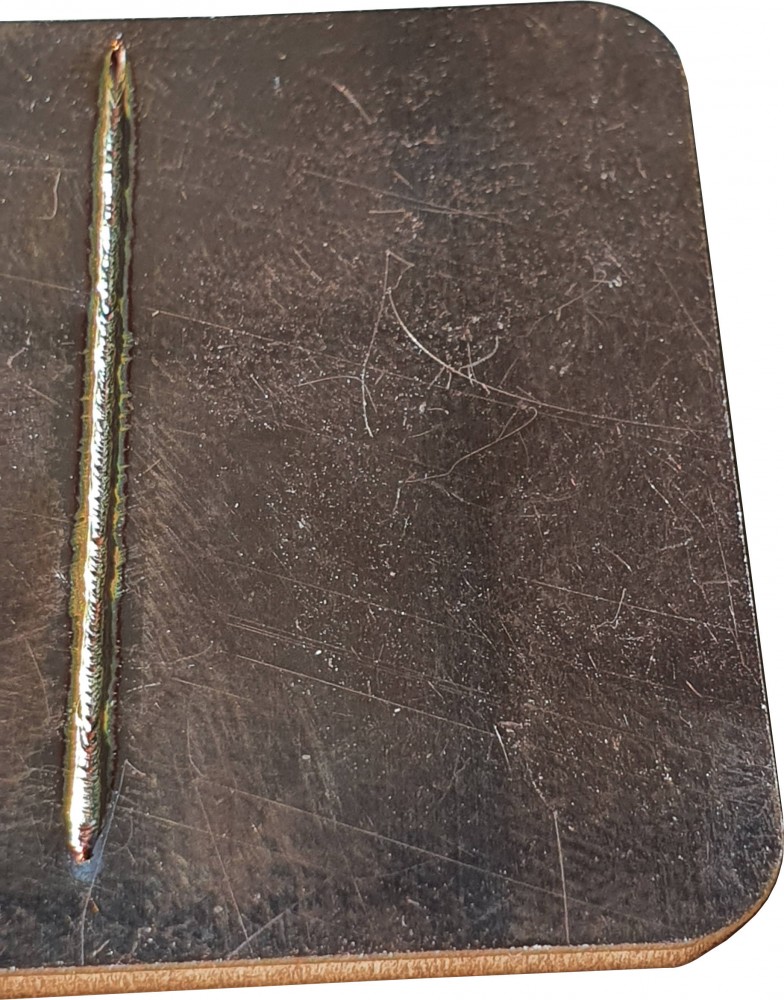

WELDING Welding is, or will be soon, certainly the process with the most important growth numerical and technological.

HARDENING Hardening is a very innovative process and for this reason not so common, but has both technical and economic advantages.

COATING This is a new and advanced way of coating and so little known even nowadays, but introduces significant advantages either technical and economic.

TWIMP safety

During the development and the industrialization of the TWIMP series machines the following points were constantly the guidelines:

- ergonomics, especially in terms of loading height

- accessibility, for daily cleaning and maintenance

- operativity, in terms of user-friendly human/machine interfacing and functioning simplification

- hygiene, related to the smokes and particles aspiration (with attention of the main table rotation)

- safety, in accordance with the actual regulation and the technical rules, in particular IEC 60825-1

TWIMP service

Some practical examples of Twimp laser applications are:

Automotive

Twip steel struts, iron shock absorber holders of not negligible dimensions, aluminium frame of electric car chargers, busbar and hairpin.

Electronics

Magnesium enclosure, steel heat sinks

Water pumps

Welding of impellers, stainless steel diffusers and threaded sleeves in bodies of pumps’ sub-assemblies, abutted shafts.

Refrigeration compressors

Dynamic holing of caps with high adaptability to different models that need to be processed.

ENG

ENG

ITA

ITA